Geopolitics vs. Your P&L: How the Red Sea Crisis Proves You Need a Supply Chain SOP.

Published on September 5, 2025 by MoreMeets Team

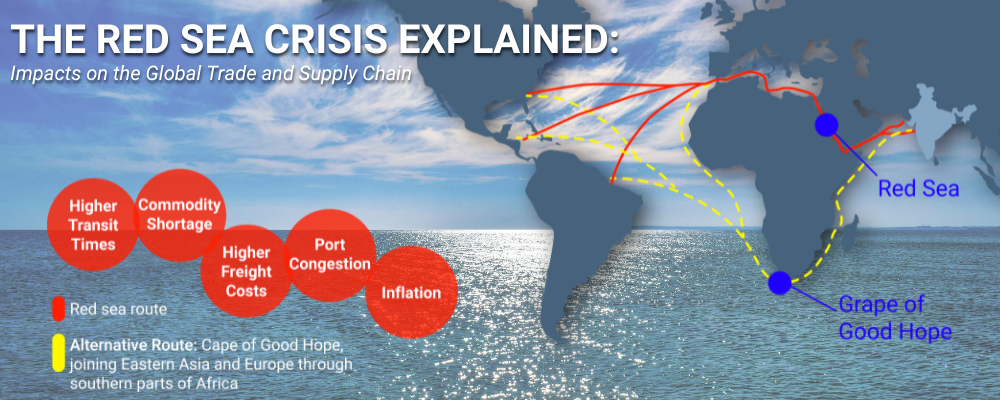

For decades, the Red Sea, leading to the Suez Canal, has been a superhighway for global trade. But starting in late 2023, this critical artery was effectively severed. A series of attacks by Houthi militants forced major shipping lines to reroute their entire fleets around Africa's Cape of Good Hope, adding weeks to transit times and millions in costs.

The result for businesses worldwide was immediate and painful: a sudden and dramatic increase in shipping costs, severe delays in receiving inventory, and production lines grinding to a halt. This crisis, much like the KFC chicken shortage, is a textbook example of a geopolitical risk rapidly morphing into a catastrophic operational and financial risk. It proves that in today's volatile world, a "just-in-time" supply chain without a "just-in-case" contingency plan is a recipe for disaster.

Failure Point 1: Critical Route Dependency

Many businesses had their entire supply chain built on the fragile assumption that the Suez Canal route would always be available. When it closed, they had no pre-planned or pre-costed alternatives, leading to panic and reactive decision-making.

Our SOP mandates a quarterly review and mapping of primary *and* secondary shipping routes for all critical supplies. Instead of scrambling, a company with this SOP would have already identified and costed the alternative route around Africa, allowing for an immediate and orderly pivot with a clear understanding of the financial impact.

Failure Point 2: "Just-in-Time" Becomes "Just-too-Late"

Lean manufacturing and minimal inventory are efficient in stable times, but without a strategic buffer, a sudden 3-week shipping delay means production lines stop cold. Many companies had no safety stock to cover the extended transit time.

The SOP requires establishing and maintaining a 'Safety Stock' level for all critical components, calculated to cover the lead time of the *secondary* shipping route, not just the primary one. This safety stock acts as a crucial buffer, bridging the gap while new shipments take the longer route and preventing costly production shutdowns.

Conclusion: Your Supply Chain is a Strategic Asset

The Red Sea crisis is not a black swan event; it is the new normal. Geopolitical instability, climate change, and pandemics have shown that supply chain disruptions are going to be a regular feature of doing business. Use the SOPs in the Logistics & Warehouse Pack to transform your supply chain from a fragile liability into a resilient, strategic advantage.

Continue Your Journey to Excellence

The concepts in this article are operationalized in the following toolkit:

Logistics & Warehouse Pack

Premium Pack

Explore The Full Toolkit